Ⅲ Izisetshenziswa Eziyinhloko

1. I-De-capper

Incazelo evamile

I-TBG300 de-capper iyisisetshenziswa sokuvala i-capping esakhiwe ngokwesidingo solayini wamanzi onemiphongolo wesivinini esingamalitha angu-5. Ukuphakama kwe-de-capping, i-tension kanye nendlela yokuvimbela imiphongolo isebenzisa isilinda sokugcoba samahhala, akukho ukungcoliswa kukawoyela, ihlanzekile futhi icocekile.

Izici Eziyinhloko

1) Sebenzisa isilinda samahhala sokugcoba, akukho ukungcoliswa kwamafutha, ihlanzekile futhi icocekile.

2) Yamukela ingalo yokuvimbela umgqomo oshintshwayo.

3) Isakhiwo sensimbi engagqwali, enhle futhi kulula ukuyihlanza.

4) Ibhulashi langaphandle

Isingeniso esifushane

I-WST300 i-brush yangaphandle iyisisetshenziswa sokuhlanza esakhiwe ngokuya ngesivinini esiphezulu kanye nesidingo solayini wamanzi onemiphongolo engamalitha ayi-5.

Izici Eziyinhloko

1) Ukuhlanza okujikelezayo kanye nomshini wokudlulisa onesakhiwo esilula esilula ukugcinwa.

2) Adopt gear transmission, fast and ezinzile.

3) Isakhiwo sensimbi engagqwali, enhle futhi kulula ukuyihlanza.

2.QGF-300 Rinser/Filler/Capper

Incazelo evamile

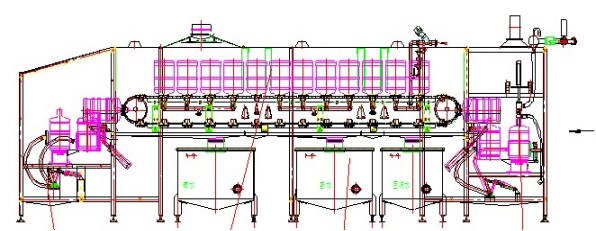

I-QGF300 rinser/filler/capper monobloc iyimishini ethuthukisiwe ethuthukiswe kusisekelo sobuchwepheshe obuthuthukile bamazwe ngamazwe futhi ngokuya ngezitayela zejubane eliphezulu kanye nokuthuthukiswa kokushintshashintsha kwesiphuzo eChina.

Izingoma Eziyinhloko

I-Rinsing/filling/capping monobloc yakhiwe ngesilayishi sebhodlela esizenzakalelayo, isihlanzi, isistimu yamapayipi, indlela yokudlulisa, isigcwalisi, kanye nedivayisi yokuthola.

I-Automatic Bottle Loader

Incazelo evamile

1) Isisekelo somshini sakhiwe ngepuleti lensimbi engagqwali kanye nepayipi lesikwele lensimbi engagqwali. Inezinzuzo zokuqina okuphezulu, ukuqina okuhle, isisindo esilula, ukubukeka okuhle, ukubuka okuhle nokuhlanza okulula.

2) Indlela yokulayisha ibhodlela isebenzisa indlela yokugingqika engu-90° isilinda, izinzile futhi inokwethenjelwa.

3) Indlela yokuphakela ibhodlela kanye nokuphusha yakhiwe i-rack pushing rack kanye nesilinda sokuphusha ibhodlela. Umsebenzi wayo ukuphusha amabhodlela ku-conveyor yebhodlela ku-hopper yokulayisha ibhodlela.

Isimiso Sokusebenza

Amabhodlela angenalutho athunyelwa ku-conveyor yokulayisha ibhodlela esuka ku-conveyor ebhodlela. Ngemuva kokuthi amabhodlela ethinte isishintshi sokuhamba esithwala amabhodlela, i-PLC yenza umsebenzi wokubala. Lapho kubalwa amabhodlela ama-4 aselungile, isilinda sokuphakela ibhodlela kanye nesiphusha sisebenza ukusunduza induku yokuphusha ibhodlela ukuze iphushe amabhodlela angenalutho kumshini wokulayisha ibhodlela ku-hopper yokulayisha ibhodlela. Ibhodlela limile ku-hopper futhi inzwa yokubona ukulayishwa kwebhodlela ithola ukuthi ibhodlela ku-hopper selilungile futhi ithumela isignali ngokushesha ukwenza isilinda esigingqisa ibhodlela eliphezulu ukuze iphushe ihopper yokulayisha ibhodlela ijike ku-90° bese iphendulela ibhodlela endaweni eleveli. . Ngalesi sikhathi, umlomo webhodlela ubheke ohlangothini oluhle lwenkomishi yokulungisa ibhodlela yesihambisi somshini wokuwasha. Inzwa yokuphusha nokulayisha ibhodlela ithola ukuthi ibhodlela selilungile futhi ukusunduzwa kwebhodlela & nokubamba izenzo zesilinda ukusunduza ibhodlela enkomishini yokulungisa yesidluliseli sesihlanza futhi ibona izinga lokulayisha amabhodlela. Iconveyor ye-rinseer ishayelwa indlela yokushayela i-riser futhi amabhodlela angenalutho aya phambili emzimbeni womshini.

Isihlambi

Incazelo evamile

1) I-riser base ishiselwe ngepuleti lensimbi engagqwali eligobile kanye nepayipi lesikwele lensimbi engagqwali. Inezinzuzo zokubukeka okuhle, ukuqina okuphezulu, ukuqina okuhle, isisindo esincane nokuhlanza okulula.

2) Iconveyor yeriser yakhiwe nge-sprocket esebenzayo ne-passive, iketango, ipuleti lokubamba ibhodlela kanye nenkomishi yokulungisa ibhodlela. Iketango kanye ne-sprocket kuklanywe kahle ukuzenza kube ngokwesayensi futhi kuphelele.

3) Indlela yokushayela i-riser iphushwa ngesilinda ukwenza ibhodlela endaweni ngayinye yokusebenza lihlale isikhathi esithile. Iketango libalwa ngokuqinile ngokuya ngokulayishwa kwebhodlela okuzenzakalelayo kanye nezindawo zokulahla ukuze kuqinisekiswe ukuma okuqondile kwakho konke ukugijima okuzenzakalelayo.

I-Filler/Capper

Incazelo evamile

I-1) Isisekelo sokugcwalisa sishiselwe ngepuleti lensimbi engagqwali egobile kanye nepayipi lesikwele lensimbi engagqwali. Inezinzuzo zokubukeka okuhle, ukuqina okuphezulu, ukuqina okuhle, isisindo esincane nokuhlanza okulula.

2) I-valve yokugcwalisa ithatha ikhanda lokugcwalisa elisha. Ngenkathi igcwalisa, isilinda yenza ukunyakaza phansi, futhi umzimba wokugcwalisa ama-valve ezemidlalo uthinta umlomo webhodlela ukuze ucindezele isiphethu kanye ne-valve yokugcwalisa evulekile.

3) Isitsha se-cap sisetshenziselwa ukugcina nokuthumela amakepisi. Uma i-cap sorter idinga isithasiselo se-caps, i-cap lifti idlulisa amakepisi esitsheni se-cap esishelelayo ama-caps aqinile futhi ngokushesha angene kusihlungi se-cap.

4) I-Cap sorter yakhiwa ikakhulukazi ithreyi ejikelezayo, i-cap chute negobolondo. Umsebenzi wayo ukuletha amakepisi asebhokisini abe yi-cap chute ngethreyi eliyindilinga elizungezayo futhi enze amakepisi e-chute aye phansi kanye nerenki ngokulandelana ngendlela ekhethekile.

5) Isisekelo se-Capper sishiselwe ngepuleti lensimbi engagqwali kanye nepayipi lesikwele lensimbi engagqwali. Inezinzuzo zokubukeka okuhle, ukuqina okuphezulu, ukuqina okuhle, isisindo esincane nokuhlanza okulula.

6) I-Capping mechanism ukwenza i-capping yebhodlela eligcwele elinekepisi ukuze kuzuzwe umphumela wokuvala. Isebenzisa i-pre-cap type capping.

7) Indlela yokufaka ibhodlela phansi yenziwe nge-hopper yokubamba ibhodlela, irack yebhodlela phansi kanye nesilinda phansi sebhodlela. Yamukela ukwakheka kwe-cylinder engu-90 °, ezinzile futhi enokwethenjelwa.

8) Indlela yokuphusha ebhodleleni yakhiwe ngepuleti lokuphusha ibhodlela, indawo yokuphusha ibhodlela nesilinda sokuphusha ibhodlela. Ikakhulukazi elokuphusha ibhodlela elihlanzekile ku-conveyor.

3. Isithuthi somgqomo

Incazelo evamile

Ukusebenza kahle komthamo wesivinini kuhlobene nokuhlelwa kwe-conveyor .Kubalulekile ukucabangela ukuma kwesikhashana okungafanele kuthinte isigaba sangaphambilini esisebenzayo kanye nokuxhumana nengxenye engakwesokunxele. Isakhiwo sethu somugqa wokukhiqiza sicabangela ngokugcwele ukutshalwa kwezimali kweklayenti nokusebenzisa kahle.

Iletha indlela yaseJalimane futhi yathuthukisa umklamo. Iningi lezingxenye lisebenzisa ukubhoboza nokugoba, okunokuqina okuhle, ukushintshana okulula nokulula. Ukuhamba okuzinzile, ukugcinwa okulula, okusebenzayo ku-diameterφ40~φ110 mm ibhodlela. Ifakwe inzwa yebhodlela egcwele esigabeni ngasinye, Zonke izigaba ziwukulawula ukuxhumana. , ehlangabezana nesidingo somkhondo.

Izici Eziyinhloko

1) Imodeli: SC00

2) Material: insimbi engagqwali

3) Injini yokuhambisa umgqomo engenalutho: 0.55KW/iyunithi

4) Injini yokuhambisa umgqomo ogcwele: 1.1KW/iyunithi

4. Ukuhlola Ukukhanya

Isingeniso esifushane

Ibhokisi lokuhlola elikhanyayo limbozwe ngensimbi engagqwali, enokukhanya okufanele nokunethezekile kwezinga lenhlanzeko likazwelonke, elingahlola ngokucacile ukungcola, okuzenzakalelayo kanye nezinhlamvu.

Idatha Yezobuchwepheshe

● Amandla wepayipi elikhanyayo: 20W

● Inombolo yepayipi elikhanyayo: 3

5.Automatic gallon film package machine

1. Ukusebenza kahle kokupakisha kuphezulu, ukusebenza ngomshini kunciphisa izindleko zabasebenzi; isivinini sokupakisha singafinyelela ku-600 imiphongolo/ihora kuya ku-2500 imiphongolo/ihora, konga izisebenzi ezimbili kuya kwezine, konga izindleko zabasebenzi ezingaba ngu-100,000 yuan ngonyaka, kodwa futhi kunciphisa kakhulu izindleko zezikhwama. Izindleko ze-membrane yesiphakamisi samabhakede amagaloni amahlanu endala yikona elingu-0.1, futhi izindleko ze-membrane yomshini wokugcwalisa othomathikhi ngokugcwele zingamaphuzu angu-6-8.

2. Ngemuva kokuvalwa kwe-shrinkage, isikhwama sebhakede sihambisana nomkhawulo wangaphandle webhakede, omuhle futhi ohlangene.

3. Ifilimu yepulasitiki ingavikela ibhakede futhi inciphise ukuguga.

Izici eziyinhloko zomshini othomathikhi we-barreled wamanzi othomathikhi zimi kanje:

1. Uhlelo lokudlulisa: Ukuguqulwa kwemvamisa kungasheshisa ukusebenza.

2. Uhlaka oluyinhloko: Uhlaka lwensimbi engagqwali engama-304.

3. Imodi yokupholisa ye-Hot-cutting: ukupholisa okuphakathi komoya okomile.

4. Imodi ye-sleeve: Imodi yokufaka ifilimu ehambisana ne-stepping motor.

5. Imodi yokuvala: Imodi yokuvala isikhwama socingo kagesi yokusika isikhwama esishisayo.

6. Imodi yokondla imigqomo: ukutholwa okuzenzakalelayo kokuphakelwa komgqomo, ukudluliswa okuzenzakalelayo.

7. Imininingwane yezisetshenziswa: 3500 mm * 850mm * 1600 mm, ibhande lokuhambisa elingu-600 mm lisuka phansi.

8. Ukucaciswa komkhiqizo okusebenzayo: I-5 gallon barrel noma umgqomo wangokwezifiso. Kudingeka imininingwane efanayo.

9. Ukucaciswa kwe-Membrane: 680-720 mm ubude, 0.006-0.015 mm ubukhulu, 350 mm ububanzi, awukho ugesi omile, inxeba eliqinile.

10. Umthwalo omkhulu wokusebenza kwezokuthutha: 20KG/0.5m/s.

11. Ukuvikela ukuphepha: ukuvikelwa kwemishini.

Isikhathi sokuthumela: Nov-30-2022