I-QGF120 rinser/filler/capper monobloc iyimishini ethuthukisiwe ethuthukiswe kusisekelo sobuchwepheshe obuthuthukile bamazwe ngamazwe futhi ngokuya ngezitayela zejubane eliphezulu kanye nokuthuthukiswa kokuzenzakalela kwesiphuzo eChina.

Izici Eziyinhloko

1) Le mishini inesakhiwo esisha, ubuchwepheshe obuthuthukisiwe, umsebenzi othembekile, ukugeleza kobuchwepheshe besayensi, ukuthuthwa kwendle okuhle kanye ne-automation ephezulu. Ukusebenza kulula. Kuyimishini efanelekile yokugcwalisa yawo wonke amabhodlela amanzi.

2) Sebenzisa indlela yamabhodlela amaningi phezulu naphansi ukuze wenze ibhodlela elingu-1 phezulu naphansi ngasikhathi sinye ukuthuthukisa ukusebenza kahle kokukhiqiza.

3) Ukukhethwa kwezinto ezibonakalayo kunengqondo. Izingxenye eziningi zisebenzisa insimbi engagqwali yekhwalithi ephezulu evela kwamanye amazwe. Ezinye izingxenye zisebenzisa izinto ezingenabuthi futhi ezihlala isikhathi eside.

I-4) Imishini eminingi ingafakwa futhi ilungiswe ngamathuluzi ajwayelekile, alungele ukushintshwa komuntu nokulungisa.

5) Inesixwayiso esiphelele sokuvikela ukuphepha. Ngenkathi ucindezela inkinobho yokumisa isimo esiphuthumayo, umshini awukwazi ukuqaliswa, futhi ukugcinwa nokufakwa kwemithamo yempahla eluhlaza kungenziwa ngalesi sikhathi.

I-6) Ukuhlolwa kwebhodlela phezulu naphansi kuhlomise ukuvikela umshini ngempumelelo.

7) I-Cap sorter ihlomisa ukubonwa kokushoda kwe-cap ukuze ulawule ukuqala nokuma kwe-cap unscrambler.

8) Uxhumano lwendlela yebhodlela phezulu naphansi nesidluliseli somshini wokuwasha wenziwa endaweni esezingeni ukuze kugwenywe ithonya lebhodlela elenqatshiwe.

9) Ukulungiswa kwegiya eliyinhloko lokushayela kanye neketanga kungenziwa ngokuqaqa ikhava lapho umshini uyeka. Faka isembozo lapho ukulungisa kuqediwe.

10) Uhlelo lomugqa we-pneumatic luhlomisa i-valve yokukhipha ingcindezi ukuze ivumelane nakho konke ukucindezela komoya okuphakelayo.

11) Isihambisi sebhodlela sithatha iketango lensimbi engagqwali phezulu ukuze kugwenywe ukugingqika kwebhodlela.

I-12) Yamukela iKhabhinethi yokulawula kagesi yensimbi engenasici. Yonke inqubo yokusebenza njengebhodlela phezulu, ukugeza amabhodlela, ibhodlela phansi nokugcwalisa kulawulwa yi-PLC.

I-13) Izingxenye zikagesi eziyinhloko (isiguquli se-frequency, i-PLC, izishintshi ze-photoelectric, i-relay) yamukela i-MITSUBISHI, i-OMRON, njll.

I-14) Uhlelo lomugqa we-pneumatic ludlula umkhiqizo we-AirTAC, njll.

Incazelo evamile

1) Isisekelo somshini sakhiwe ngepuleti lensimbi engagqwali kanye nepayipi lesikwele lensimbi engagqwali. Inezinzuzo zokuqina okuphezulu, ukuqina okuhle, isisindo esilula, ukubukeka okuhle, ukubuka okuhle nokuhlanza okulula.

2) Indlela yokulayisha ibhodlela isebenzisa indlela yokugingqika engu-90° isilinda, izinzile futhi inokwethenjelwa.

3) Indlela yokuphakela ibhodlela kanye nokuphusha yakhiwe i-rack pushing rack kanye nesilinda sokuphusha ibhodlela. Umsebenzi wayo ukuphusha amabhodlela ku-conveyor yebhodlela ku-hopper yokulayisha ibhodlela.

Isimiso Sokusebenza

Amabhodlela angenalutho athunyelwa ku-conveyor yokulayisha ibhodlela esuka ku-conveyor ebhodlela. Ngemuva kokuthi amabhodlela ethinte isishintshi sokuhamba esithwala amabhodlela, i-PLC yenza umsebenzi wokubala. Lapho kubalwa ibhodlela elingu-1 selilungile, isilinda sokuphakela ibhodlela kanye nokuphusha sisebenza ukusunduza induku yokuphusha ibhodlela ukuze iphushe amabhodlela angenalutho kumshini wokulayisha ibhodlela ku-hopper yokulayisha ibhodlela. Ibhodlela limile ku-hopper futhi inzwa yokubona ukulayishwa kwebhodlela ithola ukuthi ibhodlela ku-hopper selilungile futhi ithumela isignali ngokushesha ukwenza isilinda esigingqisa ibhodlela eliphezulu ukuze iphushe ihopper yokulayisha ibhodlela ijike ku-90° bese iphendulela ibhodlela endaweni eleveli. . Ngalesi sikhathi, umlomo webhodlela ubheke ohlangothini oluhle lwenkomishi yokulungisa ibhodlela yesihambisi somshini wokuwasha. Inzwa yokuphusha nokulayisha ibhodlela ithola ukuthi ibhodlela selilungile futhi ukusunduzwa kwebhodlela & nokubamba izenzo zesilinda ukusunduza ibhodlela enkomishini yokulungisa yesidluliseli sesihlanza futhi ibona izinga lokulayisha amabhodlela. Iconveyor ye-rinseer ishayelwa indlela yokushayela i-riser futhi amabhodlela angenalutho aya phambili emzimbeni womshini.

Incazelo evamile

1) I-riser base ishiselwe ngepuleti lensimbi engagqwali eligobile kanye nepayipi lesikwele lensimbi engagqwali. Inezinzuzo zokubukeka okuhle, ukuqina okuphezulu, ukuqina okuhle, isisindo esincane nokuhlanza okulula.

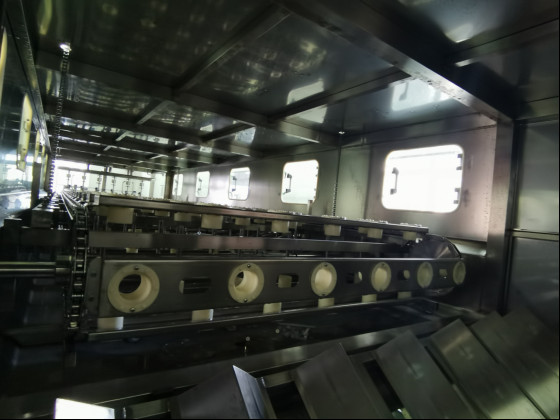

2) Iconveyor yeriser yakhiwe nge-sprocket esebenzayo ne-passive, iketango, ipuleti lokubamba ibhodlela kanye nenkomishi yokulungisa ibhodlela. Iketango kanye ne-sprocket kuklanywe kahle ukuzenza kube ngokwesayensi futhi kuphelele.

3) Indlela yokushayela i-riser iphushwa ngesilinda ukwenza ibhodlela endaweni ngayinye yokusebenza lihlale isikhathi esithile. Iketango libalwa ngokuqinile ngokuya ngokulayishwa kwebhodlela okuzenzakalelayo kanye nezindawo zokulahla ukuze kuqinisekiswe ukuma okuqondile kwakho konke ukugijima okuzenzakalelayo.

Isimiso Sokusebenza

Lapho ibhodlela lingena enkomishini yokulungisa yesidluliseli sesihlanzi ngesisetshenziswa esizenzakalelayo sokulayisha ibhodlela, amajaji enzwa kukhona ibhodlela eketango bese eqala isilinda esikhulu sokushayela ukuze sisebenze. Ngesikhathi esifanayo, i-PLC ithola isignali yokwenza iphampu yamanzi e-recyle, iphampu yamanzi e-alkali, impompo yesibulala-magciwane kanye nephampu yamanzi yomkhiqizo iqale ukusebenza. Ibhodlela lingena kancane kancane kumkhiqizi ukuze lihlanjululwe. I-rinser ilawulwa yi-PLC. Umjikelezo ngamunye wokuwasha weketango lokuwasha uzohamba ngebanga elifanayo ukuze wenze umlomo webhodlela ubhekane nekhanda eliwashayo endaweni ngayinye yokuwasha ukuze ubone ukusebenza okuhambisanayo kwenkomishi yokulungisa amabhodlela kanye nenetha layo nombhobho wesifutho. Ngenkathi ibhodlela liqeda wonke umjikelezo wokuwasha, isixhumi sokuhlanza sibeka ibhodlela elihlanzekile ukuze liphume ebhodleleni futhi ibhodlela lisesimweni sokubeka izinga.

Incazelo evamile

I-1) Isisekelo sokugcwalisa sishiselwe ngepuleti lensimbi engagqwali egobile kanye nepayipi lesikwele lensimbi engagqwali. Inezinzuzo zokubukeka okuhle, ukuqina okuphezulu, ukuqina okuhle, isisindo esincane nokuhlanza okulula.

2) I-valve yokugcwalisa ithatha ikhanda lokugcwalisa elisha. Ngenkathi igcwalisa, isilinda yenza ukunyakaza phansi, futhi umzimba wokugcwalisa ama-valve ezemidlalo uthinta umlomo webhodlela ukuze ucindezele isiphethu kanye ne-valve yokugcwalisa evulekile.

3) Isitsha se-cap sisetshenziselwa ukugcina nokuthumela amakepisi. Uma i-cap sorter idinga isithasiselo se-caps, i-cap lifti idlulisa amakepisi esitsheni se-cap esishelelayo ama-caps aqinile futhi ngokushesha angene kusihlungi se-cap.

4) I-Cap sorter yakhiwa ikakhulukazi ithreyi ejikelezayo, i-cap chute negobolondo. Umsebenzi wayo ukuletha amakepisi asebhokisini abe yi-cap chute ngethreyi eliyindilinga elizungezayo futhi enze amakepisi e-chute aye phansi kanye nerenki ngokulandelana ngendlela ekhethekile.

5) Isisekelo se-Capper sishiselwe ngepuleti lensimbi engagqwali kanye nepayipi lesikwele lensimbi engagqwali. Inezinzuzo zokubukeka okuhle, ukuqina okuphezulu, ukuqina okuhle, isisindo esincane nokuhlanza okulula.

6) I-Capping mechanism ukwenza i-capping yebhodlela eligcwele elinekepisi ukuze kuzuzwe umphumela wokuvala. Isebenzisa i-pre-cap type capping.

7) Indlela yokufaka ibhodlela phansi yenziwe nge-hopper yokubamba ibhodlela, irack yebhodlela phansi kanye nesilinda phansi sebhodlela. Yamukela ukwakheka kwe-cylinder engu-90 °, ezinzile futhi enokwethenjelwa.

8) Indlela yokuphusha ebhodleleni yakhiwe ngepuleti lokuphusha ibhodlela, indawo yokuphusha ibhodlela nesilinda sokuphusha ibhodlela. Ikakhulukazi elokuphusha ibhodlela elihlanzekile ku-conveyor.

Isimiso Sokusebenza

Ibhodlela elihlanjululwe ligingqika ngomshini webhodlela phansi futhi liphushelwa kusidluliseli sokugcwalisa kanye nesigcwalisi ngomshini wokuphusha webhodlela, lapho i-PLC ithola isignali futhi ithumela inkomba yokuqala ukugcwalisa ama-valve ukwenza ukugcwalisa ibhodlela. Ngenkathi amabhodlela angu-4 egcwele, ibhodlela elivimbile kanye nokubamba liyabuya futhi ibhodlela liya phambili, bese idivayisi yokulenga ikepisi ilenga ikepisi yebhodlela eligcwalisiwe. Ukufaka i-capping kwenziwa lapho ibhodlela lifika kudivayisi yokufaka i-capping. Ibhodlela eliqediwe lithunyelwa enqubweni elandelayo ngebhodlela-out conveyor.

Amapharamitha amakhulu

| NO | Into | Idatha |

| 1. | Amandla | 120-150 BPH |

| 2. | Isakhiwo seziteshi zokugeza (iziteshi ezingu-6 sezizonke) | I-1-time disinfecting water internal |

| 3. | Ukuconsa isikhathi esingu-1 | |

| 4. | Isikhathi esingu-1 sokubuyisela kabusha amanzi | |

| 5. | Ukugeza ngamanzi omkhiqizo wesikhathi esi-2 | |

| 6. | Ukuconsa isikhathi esingu-1 | |

| 7. | Amandla afakiwe(amandla aphelele) | 3.8KW |

| 8. | Umoya ocindezelwe | 0.6m3/min, 0.4-0.6 MPA |

| 9. | Isihlanganisi somoya esicindezelwe | φ12 mm |

| 10. | Amanzi okugeza axhunywe ngaphandle | 8m3/min,0.35⽞0.5Mpa |

| 11. | Inhlanganisela yokuhlanza amanzi yomkhiqizo | φ40 mm |

| 12. | Ukugeza okuhlangene kokuphakelwa kwamanzi | φ52 mm |

| 13. | Ukugcwalisa amanzi axhunyiwe | 15m3/imizuzu,0.25~0.3Mp |

| 14. | Ukugcwalisa okuhlangene | φ70mm |

| 15. | I-outlet yokukhipha | φ70mm |

| 16. | Isikhathi sokugeza esisebenzayo | 18sec. |

| 17. | Ubukhulu (mm) | 3550×700×1580 (L*W*H) |

| 18. | Isisindo | 600 Kg |

-

umshini wokugcwalisa isiphuzo esine-carbonated

-

Umshini Wokugcwalisa Ubhiya we-Glass Botte

-

Umshini Wokugcwalisa Ijusi Le-PET Bottle

-

I-Aluminium ingagcwalisa Umshini Wokugcwalisa Iziphuzo Ze-Carbonated

-

Umshini wokugcwalisa uwoyela we-piston wohlobo lwe-Linear

-

Umshini wokugcwalisa amanzi ophuzwayo we-PET